Superior Protection Against Environmental Factors

Gelcoat Resin is a high-performance material widely used in marine, automotive, and construction industries to provide a protective outer layer for fiberglass structures. This specialized resin acts as a barrier against harsh environmental conditions, including UV rays, moisture, and chemical exposure. Its non-porous surface prevents water absorption, reducing the risk of degradation and extending the lifespan of the underlying material. Industries that rely on fiberglass components choose gelcoat resin for its exceptional resistance to corrosion and its ability to maintain structural integrity even in extreme conditions.

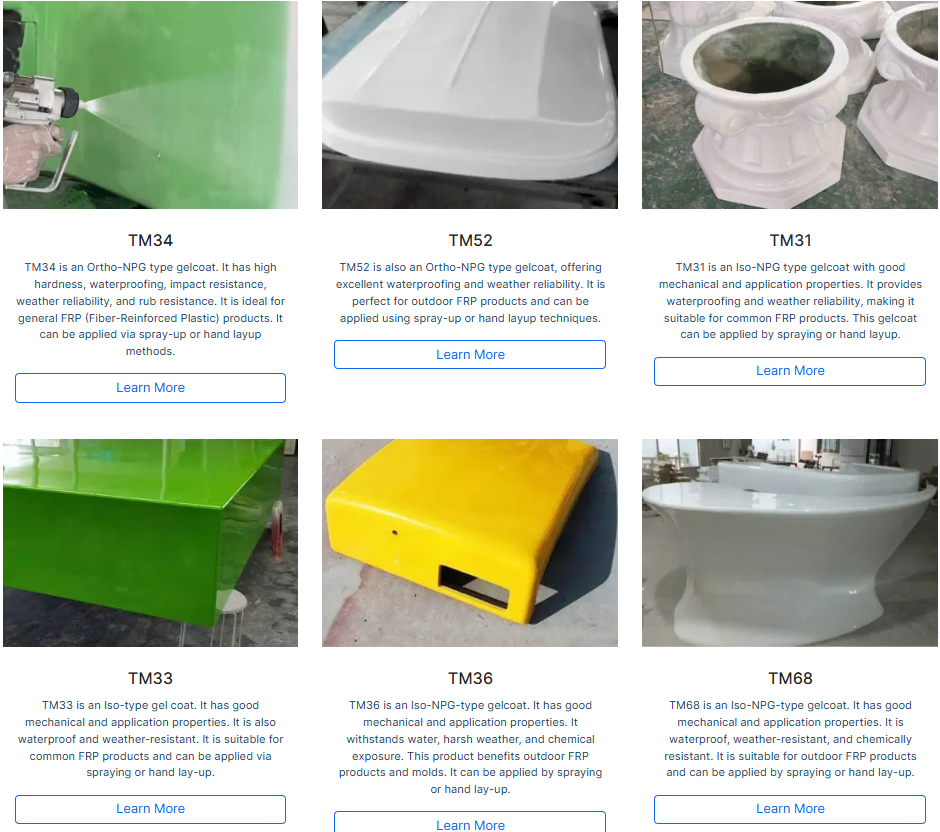

Enhancing Aesthetic Appeal with a Smooth Finish

Beyond protection, gelcoat resin plays a crucial role in enhancing the visual appeal of surfaces by offering a glossy, uniform finish. Available in various colors and formulations, it allows manufacturers to achieve a polished appearance without requiring additional painting or finishing processes. The smooth texture of gelcoat resin not only adds a premium look but also contributes to ease of maintenance, as dirt and stains can be effortlessly wiped away. Whether used in boat hulls, vehicle exteriors, or architectural panels, this resin ensures a professional and long-lasting aesthetic effect.

Application Techniques for Maximum Efficiency

Applying gelcoat resin requires precision to achieve optimal results. It is typically sprayed or brushed onto a mold before the fiberglass layers are added, ensuring a strong bond between the coating and the structure. Proper curing techniques, including controlled temperature and humidity, are essential for achieving maximum durability and a flawless surface. By following the correct application methods, industries can harness the full potential of gelcoat resin, ensuring superior performance and longevity in their products.